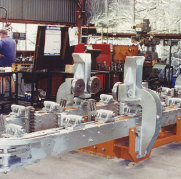

In January 2022, our company moved into our new special-purpose building adjacent to our original building, significantly improving our productivity. In addition, this expansion has dramatically enhanced our lean manufacturing processes. It has also provided us with a greater capacity for under roof space and greatly improved safety for our employees, suppliers, and clients.

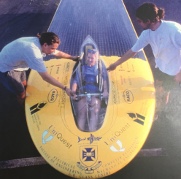

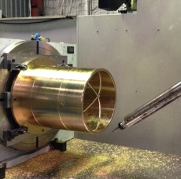

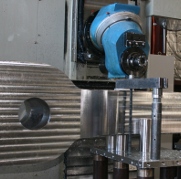

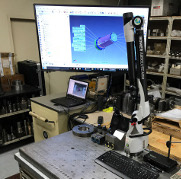

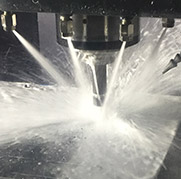

Hillier Engineering Services continues to invest heavily in state-of-the-art quality machine tools and equipment. We are incredibly proud to have such highly skilled, loyal machine operators who work with our energetic management team and are committed to ensuring our clients' components meet their required specifications.

Hillier Engineering Services have developed strong relationships with our suppliers to ensure they meet our strict standards for quality and reliability. Our suppliers are crucial to our manufacturing process and supply chain. For Hillier Engineering Services to meet our clients' time delivery targets, all our suppliers must stay committed to our delivery, quality and requirements.

On-time delivery, quality, safety, and competitive pricing are our key focus for our clients. Our company is ISO9001:2015 accredited to ensure our manufacturing processes are compliant and efficient to provide our clients with the highest level of service.

Hillier Engineering Services are a known machining supplier in meeting tight deadlines and are fast at reacting to clients' needs as they arise.

Our future is supplying our clients with the quality machined components they require.

Our friendly competent staff are here to help with whatever machining requirements you have. Look no further as "We Never Comprise on Quality".