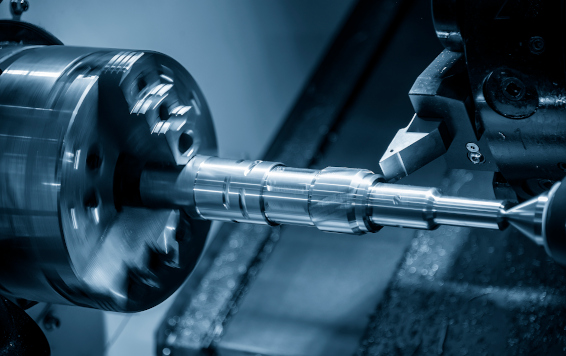

CNC Machining

Hillier Engineering Services have offered exceptional CNC Machining services since we purchased our first CNC lathe in 1992. Our highly skilled CNC operators are trained and take great pride in producing quality work. As a result, we can handle large orders while maintaining tight tolerances and exceptional quality.

CNC Turning

The types of CNC components we can CNC Turn are wide-ranging. We have a proven track record of machining most grades and types of materials. We are familiar with machining billets, castings, forgings, and fabrications. In addition, we use the latest cutting tool technology; ensuring components meet our clients' specifications.

We use the latest machining technology and run our machines at optimal performance levels.

We can offer fast turnaround times, cost-efficient solutions, and high-quality components at Hillier Engineering Services CNC Turning services.

Some of our CNC lathes can use machine steadies and four jaw chucks to enable safe and reliable machining services.

While steels and alloys are most of the CNC turning services we offer, we can machine components of various types and grades out of plastic.

Some of the machined components we can CNC Turn are:

- Bearing housings

- Bearing retainers

- Couplings

- Duo Cones

- End caps

- Hubs

- Impellors

- Shafts

- Sheaves

- Sleeves

- Spherical housings

- Pistons

- Pins

- Special bolts

- Steel wheels

- Tapered pins

Our diverse range of clients across many industries is where our CNC Turning experience has developed.

We have also been able to help our clients find solutions and offer better designs to make the machining process more efficient and cost-effective.

If you require CNC Turning services, contact us and experience the difference in precision, quality, and service.