Quality Inspection Services

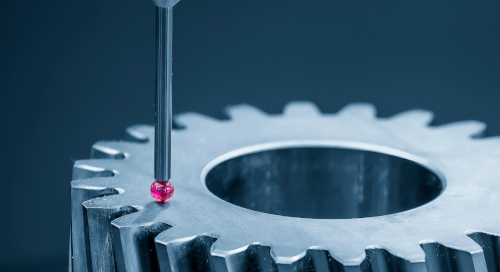

Hillier Engineering Services recognises the importance of quality assurance in precision machining, and that is why we have a dedicated temperature-controlled inspection laboratory.

Quality Inspection Services (QIS)

All finished machined components pass through a final inspection process, to ensure components meet the required specification.

Components are checked either manually, using traditional measuring equipment such as micrometres, slip gauges, thread gauges and verniers or by using Coordinate Measuring Machines (CMM) technology.

If our clients require CMM reporting, we can offer two types of CMM inspections; Portable CMM - allows for in-process measurement inspections while the component is still in the machine whilst our Flat Bed CMM - enables detailed measurements and inspections once the component is removed from the machine.

Both CMMs produce a variety of Quality Assurance (QA) inspection reports, including:

- First Article Reports

- PPAP Reports

- Customised Inspection reports.